STEAM AUTOCLAVE, STERILIZER "ZAGOTOVSHIK" 26 LITERS

Autoclave "Zagotovshik" is an indispensable assistant in the preparation of home-made products such as stew, canned fish, cereals, pickled tomatoes, crispy pickles, salads, lecho, pates, caviar, mushrooms and berry jam.

No more spending hours and hours rolling jars the traditional way. Together with the "Zagotovshik" autoclave, you can cook 24 cans of home-cooked meals for the whole family at a time, the cooking time will be up to 60 minutes.

STEAM COOKING

100% NATURAL

WORKS ON ALL STOVES

- The innovative lid closing construction is convenient, any housewife can handle it, spending 5 minutes preparing the autoclave for work.

- The autoclave is equipped with a functional breathing valve that can release excess air when heated, and when cooled, normalize the pressure inside the autoclave for easy and safe opening of the lid.

- The "Zagotovshik" autoclave is reliable due to the precise working of the emergency valve, which is equipped with a hose with a vaporizer to safely disperse the steam in case the pressure exceeds the allowable one.

Evaluate the benefits of purchasing the autoclave "Zagotovshik":

Steam autoclaving – economical, tasty, natural

Save time and money with the autoclave "Zagotovshik":

- For assembly - saving up to 5 times. Convenient wing nuts are twisted easily and quickly, no need to use a special key.

- For water - saving up to 6 times. There is no need to completely fill the autoclave with water, only a few liters are required for operation.

- For canned food - saving up to 4 times. You do not have to wait for hours for the autoclave to start working.

-

For electricity, energy and gas - savings up to 6 times.

To start the workflow, you need to heat only 2 liters of water.

Use twist-off lids for easy and convenient preservation

The classic lids are slowly becoming a thing of the past, as they are labor intensive to use, and sterilization in an autoclave requires a special pressure cassette. Otherwise, when the cans are heated in an autoclave, the pressure in them increases rapidly and breaks the hermetically sealed lids.

Autoclave "Zagotovshik" - a reliable assistant in every kitchen

With the autoclave "Procurer" you can spend a minimum of time on conservation, without any hassle you can make homemade preparations for the whole family.

At the same time, the autoclave has compact dimensions and is absolutely safe in operation.

Characteristics of the autoclave "Zagotovshik" 26 liters

|

Height

| 525 mm |

| Diameter | 300 mm |

| Volume | 26 liters |

| Working temperature | 120 degrees |

|

Working pressure

| 1-1.2

atmospheres

|

| Weight | 7.7 kg |

Capacity of autoclave "Zagotovshik"

There are many sizes of glass jars, they all different in height and diameter, even jars of the same volume can different in height and diameter, respectively, the capacity of the autoclave will be different when using different jars. For an approximate calculation of the capacity of jars in an autoclave, it is necessary to use the dimensions of the usable internal volume.

The capacity of the autoclave "Zagotovshik" 26 liters in jars of various sizes

0.25 liters - 60*85 mm -

8 in a row

- 48 pcs.

0.5 liters - 117*88 mm - 8

in a row

- 24 pcs.

0.7 liters - 133*95 mm - 7 in a row - 14 pcs.

0.95 liters - 165*100 mm - 5 in a row - 10 pcs.

2 liters - 205*130 mm - 3 in a row - 3 pvs.

3 liters - 235*153 mm - 1 in a row - 1 pc.

Sophisticated security system

The breathing valve works in a two-way mode (for opening and closing). Due to the unique construction, the valve, when the autoclave is heated, releases excess air from the tank, then closes and remains closed throughout the cooking time. As the tank cools, the pressure in the tank decreases, the valve opens and lets in air, so you will not experience any difficulties opening the lid.

The breathing valve works in a two-way mode (for opening and closing). Due to the unique construction, the valve, when the autoclave is heated, releases excess air from the tank, then closes and remains closed throughout the cooking time. As the tank cools, the pressure in the tank decreases, the valve opens and lets in air, so you will not experience any difficulties opening the lid.

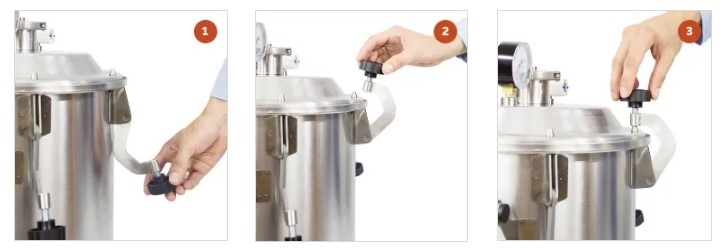

The lid is fixed with a special clamping system. To close the lid, it is enough to throw on the clamps and fix them by wing nuts. The lid closing system is convenient, simple, reliable and safe, no need to use a special key. It will take you a minimum of time to place the lid, and improper fastening, which can cause an emergency, is completely excluded.

The lid is fixed with a special clamping system. To close the lid, it is enough to throw on the clamps and fix them by wing nuts. The lid closing system is convenient, simple, reliable and safe, no need to use a special key. It will take you a minimum of time to place the lid, and improper fastening, which can cause an emergency, is completely excluded.

When the emergency valve is activated, a powerful jet of hot steam comes out of it, which with a high degree of probability becomes the cause of serious burns. We have done everything to eliminate the risk of burns, the use of the "Zagotovshik" autoclave is as safe as possible. A hose is installed on the valve fitting, for fastening strength it is pressed with a clamp, and at the other end of the hose a diffuser is placed on the clamp connection, which is placed in an empty jar during autoclave operation.

When the emergency valve is activated, a powerful jet of hot steam comes out of it, which with a high degree of probability becomes the cause of serious burns. We have done everything to eliminate the risk of burns, the use of the "Zagotovshik" autoclave is as safe as possible. A hose is installed on the valve fitting, for fastening strength it is pressed with a clamp, and at the other end of the hose a diffuser is placed on the clamp connection, which is placed in an empty jar during autoclave operation.

The diffuser construction ensures the distribution of the steam flow, respectively, its pressure decreases. The weight of the diffuser does not allow the hose to move randomly.

The diffuser construction ensures the distribution of the steam flow, respectively, its pressure decreases. The weight of the diffuser does not allow the hose to move randomly.

ATTENTION! IT IS DANGEROUS TO WORK WITHOUT A DIFFUSER!

ATTENTION! IT IS DANGEROUS TO WORK WITHOUT A DIFFUSER!

How to work on the autoclave "Zagotovshik"

1 step: Choose food for preservation, for example, you can cook turkey meat. Rinse thoroughly, remove excess and cut the meat into small pieces.2 step: Arrange the chopped meat on the jars, laying it loosely, leaving free space to the top of the jar. According to the recipe, add salt, sugar and other spices. Add water if necessary.

3 step: Use twist-off lids for hermetic closure. Screw the lids on the jars tightly by hand. Place the false bottom into the autoclave, fill with about 2 liters of water. Place jars. When loading other level, use an additional false bottom.

4 step: Place the lid on the gasket in the center, the gaps should be equal on all sides. Place the clamps on the conical platforms and fix them by twisting the wing nuts in pairs opposite each other. Check the fastening of the hose on the emergency pressure relief valve, lower the other end of the hose with the diffuser into an empty container.

5 step: Place the autoclave on the stove. Turn on the heating, wait for the valve to close (at full load for about an hour), bring the temperature up to 120 degrees. Turn down the power and cook at a temperature of 120 degrees and a pressure of 1.2 atmospheres in time according to the recipe.

6 step: Turn off the heat, let the autoclave cool for one hour before opening the valve. Remove jars carefully. Wait for the autoclave to cool completely, drain the water, wash and dry the autoclave.

Additional equipment for the autoclave "Zagotovshik"

The autoclave is compatible with any distillation column with a 2" clamp connection (not included). For example, "Yastreb" 2 inches with a steam selection unit and simple control in any mode.It is enough to remove the breathing valve, place the column on the clamp connection and connect the cooling.

Reliable construction of the autoclave "Zagotovshik"

In the autoclave "Procurer" everything is under control, its use is absolutely safe. You do not have to worry that some node will not work or will work incorrectly. The results of our testing confirm that everything works accurately and without failures.

Autoclave "Zagotovshik" is:

Tank 26 liters

-

With reinforced bottom and stiffeners for safe use.

-

With comfortable branded handles and a special clamping system on polyurethane wing nuts.

Dome lid

- With thoughtful and proven construction for comfortable exploitation.

- With 2" tri-clamp connection to place the column as a distillation apparatus.

Tank design features – maximum quality in every detail

Reinforced bottom with stiffeners

At the bottom there are special stiffening ribs, which are formed under a pressure of 100 tons using a hydraulic press. Due to this, the bottom practically does not deform under the influence of pressure and high temperature, while maintaining a stable shape during exploitation.

The container is easy to clean after use, as there are no hard-to-reach places in it. Smooth weld seams due to modern welding technology. The surface of the autoclave is ideally smooth not only outside, but also inside.

Clamping system - reliable and simple as one-two-three

Another element of security. The lid closes with 6 clips, which are made of a 4 mm thick bracket. You don't need a special key to securely lock the lid, fixing is quick and easy.

The method of fixing the clamp is threaded. There is a small notch on the stud that exactly fits on the conical platform on the dome lid. Once the clamps are in place, simply tighten the wing nuts, which are made of heat-resistant polymer. It takes very little effort to tighten them, so even a fragile woman can easily cope with this task.

The method of fixing the clamp is threaded. There is a small notch on the stud that exactly fits on the conical platform on the dome lid. Once the clamps are in place, simply tighten the wing nuts, which are made of heat-resistant polymer. It takes very little effort to tighten them, so even a fragile woman can easily cope with this task.Thick silicone gasket made of durable and safe material

It withstands temperatures over 200 °C. The thickness of the gasket is chosen in such a way that the lid can be easily placed and complete tightness of the connection is ensured.

It withstands temperatures over 200 °C. The thickness of the gasket is chosen in such a way that the lid can be easily placed and complete tightness of the connection is ensured.

Unique development, recognizable part of equipment. Branded handles do not heat up, are comfortable to grip, make using the autoclave even more comfortable and safe.

Unique development, recognizable part of equipment. Branded handles do not heat up, are comfortable to grip, make using the autoclave even more comfortable and safe.

Branded false bottom

It is intended for stability of the loaded jars on the lower level of the autoclave. The autoclave complectation includes a flat false bottom, which has a special flanging, which allows jars to confidently sit in the container and withstand the weight of jars. We also offer for purchase a false bottom for the 2nd and 3rd levels.

It is intended for stability of the loaded jars on the lower level of the autoclave. The autoclave complectation includes a flat false bottom, which has a special flanging, which allows jars to confidently sit in the container and withstand the weight of jars. We also offer for purchase a false bottom for the 2nd and 3rd levels.

Our priorities are your safety, as well as the reliability and durability of products

Therefore, for the manufacture of the autoclave, food grade AISI 430 stainless steel is used with an optimal ratio of price and technical characteristics.

- This grade of stainless steel is approved for use in the food industry due to the presence of a large amount of chromium (16-18%) in the composition. Steel does not affect the composition and taste of products when in contact.

-

The composition of the material provides resistance to temperature extremes, as well as rapid heating and cooling, which means saving time and energy.

-

AISI 430 is able to simultaneously withstand high temperature and mechanical loads (properties are maintained at temperatures above 800 degrees!).

-

Due to the ferritic composition of the material, the autoclave "Zagotovshik" works on all types of stoves (gas, electric, ceramic, induction).

-

AISI 430 steel grade refers to alloys with maximum corrosion resistance - its service life is several decades.

Thoughtful safety group on the dome lid

On the dome lid, metal thickness 2 mm, there are 6 conical platforms for clamps. Also, the construction of the lid includes a well-thought-out security system and everything you need for convenient work:

Digital thermometer located in a blind sleeve Measurement range from -50 to +300 degrees.

The thermometer is highly accurate, has a compact size, the measurement step is 0.1 degrees. Instantly responds to changes in the current temperature.

Measurement range from -50 to +300 degrees.

The thermometer is highly accurate, has a compact size, the measurement step is 0.1 degrees. Instantly responds to changes in the current temperature.

Manometer with a diameter of 63 mm with a well-read indication

The manometer (pressure gauge) has been verified, certified and manufactured in accordance with all requirements. The working pressure of the autoclave is 1-1.2 atmospheres. The pressure gauge displays the excess pressure, which is 1 atm less than the absolute pressure. Excessive pressure increases the sterilization temperature.

The manometer (pressure gauge) has been verified, certified and manufactured in accordance with all requirements. The working pressure of the autoclave is 1-1.2 atmospheres. The pressure gauge displays the excess pressure, which is 1 atm less than the absolute pressure. Excessive pressure increases the sterilization temperature.

1.5 bar overpressure valve

The emergency valve of the "Zagotovshik" autoclave is activated when a pressure of 1.5 bar is reached. When activated, it opens and releases excess steam, which is discharged through a hose. To ensure the safety of equipment operation, a diffuser is connected to the 2nd end of the hose, which distributes steam into streams, eliminating the risk of the hose flying out of the can.

The emergency valve of the "Zagotovshik" autoclave is activated when a pressure of 1.5 bar is reached. When activated, it opens and releases excess steam, which is discharged through a hose. To ensure the safety of equipment operation, a diffuser is connected to the 2nd end of the hose, which distributes steam into streams, eliminating the risk of the hose flying out of the can.

ATTENTION! USING THE AUTOCLAVE WITHOUT A DIFFUSER HOSE IS A SAFETY BREACH. IN THIS CASE THERE IS A RISK OF BURNING WHEN THE VALVE ACTIVATES.

ATTENTION! USING THE AUTOCLAVE WITHOUT A DIFFUSER HOSE IS A SAFETY BREACH. IN THIS CASE THERE IS A RISK OF BURNING WHEN THE VALVE ACTIVATES.

Washer with breathable valve with silicone membrane on the clamp cover

Mounting type - clamp with gasket. The valve performs 2 functions: when the autoclave is heated, air escapes through it, which is displaced by water vapor. After the steam fills the entire volume of the tank, the valve will close. This ensures that no vacuum will be created in the container and the lids of the jars will not be torn off.

Mounting type - clamp with gasket. The valve performs 2 functions: when the autoclave is heated, air escapes through it, which is displaced by water vapor. After the steam fills the entire volume of the tank, the valve will close. This ensures that no vacuum will be created in the container and the lids of the jars will not be torn off.

The tightness of the valve is provided by a silicone membrane. When the autoclave cools down, the valve opens and lets air in. This ensures that no vacuum will be created in the container and the lids of the jars will not be torn off.

The tightness of the valve is provided by a silicone membrane. When the autoclave cools down, the valve opens and lets air in. This ensures that no vacuum will be created in the container and the lids of the jars will not be torn off.

2 inch clamp

2" clamp provides equipment versatility. You can place a column on the tank and use it as a distillation apparatus. The column, if necessary, can be further upgraded to expand the possibilities in the preparation of home-made alcoholic beverages.

2" clamp provides equipment versatility. You can place a column on the tank and use it as a distillation apparatus. The column, if necessary, can be further upgraded to expand the possibilities in the preparation of home-made alcoholic beverages.

Complectation of the autoclave "Zagotovshik": immediately ready for use

The basic package includes everything you need to get started. You do not have to waste time looking for additional components, after receiving the autoclave, you can immediately start cooking. Its construction can withstand pressure up to 4 atmospheres. Due to the wall thickness of 1 mm, the autoclave "Zagotovshik" will exploid for several decades, subject to the rules of care.

Each autoclave is tested by technical control. The equipment is tested for the correct operation of the valve and manometer (pressure gauge), possible leaks.

Specifications of the autoclave "Zagotovshik" 26 liters

Tank

| Material of manufacture | AISI 430 stainless steel |

| Volume | 26 liters |

|

Autoclave assembly height

| 525 mm |

|

Tank inner height

| 350.5 mm |

| Tank diameter | 300 mm |

|

Tank inner diameter

| 298 mm |

| Bottom thickness

| 1.5 mm |

|

Wall thickness

| 1 mm |

|

Clamp thickness

| 4 mm |

|

False bottom thickness

| 0.8 mm |

| Autoclave weight, net | 7.7 kg |

| Autoclave weight, gross | 9.2 kg |

|

Clamp handle material

|

polyurethane plastic

|

|

Working temperature

| 120 degrees |

|

Working pressure

|

1-1.2 atmospheres

|

Lid (cover)

| Material of manufacture

| AISI 430 stainless steel |

|

Cover thickness

| 2 mm |

|

Clamp outlet

| 2 inches |

|

Breathing valve

|

two-sided

|

|

Emergency valve

| 1.5 bar |

|

Thermometer

| digital |

| Thermometer mounting sleeve

| blind |

| Manometer | 63 mm diameter |

Complectation of the autoclave "Procurer" 26 liters

| Autoclave tank 26 liters | 1 pc. |

|

Silicone gasket, 4 mm

| 1 pc. |

|

Dome cover (lid) with 2" clamp

| 1 pc. |

| 2" clamp with silicone gasket

| 1 pc. |

| Manometer 63 mm | 1 pc. |

|

Excess pressure valve, 1.5 atm.

| 1 pc. |

|

Hose 1 m for pressure relief

| 1 pc. |

|

Diffuser (steam suppressor)

| 1 pc. |

|

Washer with breathable valve and silicone gasket

| 1 pc. |

| Digital thermometer | 1 pc. |

|

Wing nuts-handles on a threaded connection

| 6 pcs. |

|

False bottom for jars | 1 pc. |

|

Product data sheet

| 1 pc. |

Producer - Zagotovshik

Cart

Cart is empty.